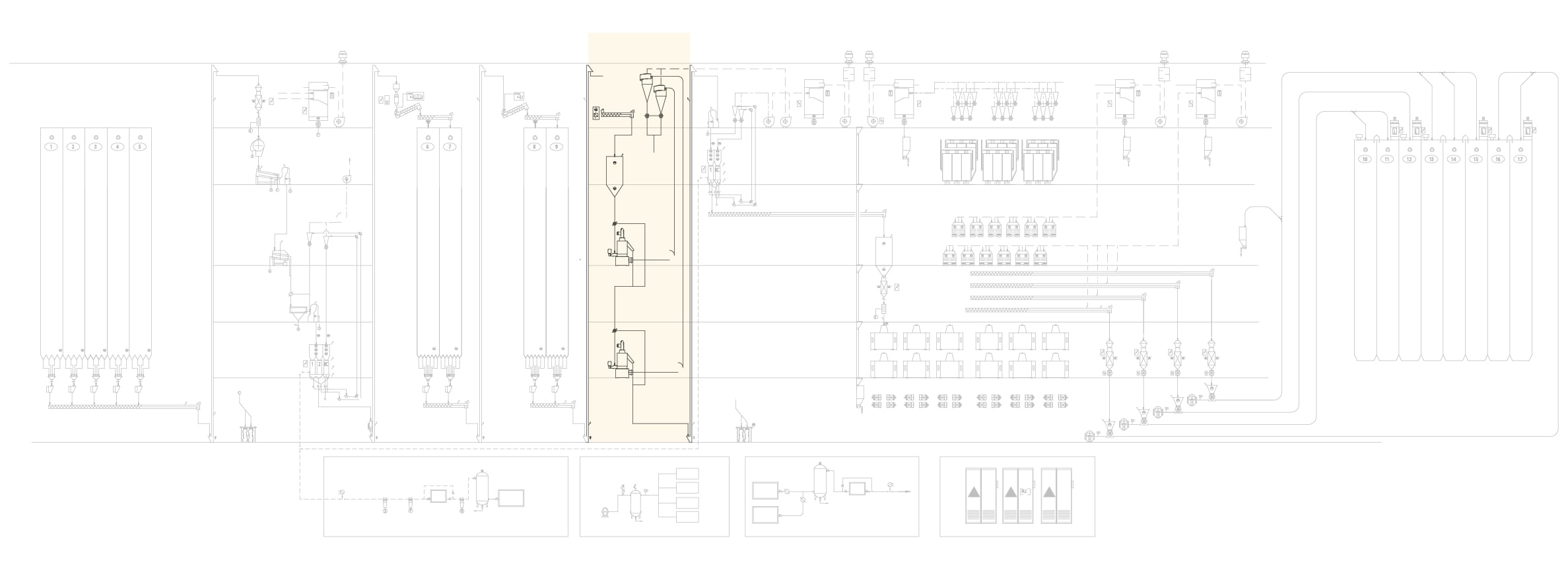

Husking

A first and fundamental step in cleaning the cereal is the decortication that makes the finished products of the grinding healthy and safe and of better quality.

While in the past the cereal was ground and then the bran part was removed from the ground product, the decortication process proceeds in reverse, eliminating the outermost layers of the cereal before grinding. Placing upstream of the production process, it is configured as a preventive treatment of the cereal which serves to eliminate a large part of the bran and impurities, contaminations, etc. present, before proceeding with grinding.

The first and most important effect of decortication is to obtain safe finished products, free from harmful residues that can accumulate on the outermost part of the cereal and of superior quality by decreasing the quantity of the ash content. The abrasion of the surface layers of bran, in fact, allows us to break down the bacterial load and eliminate residues of pesticides that may be used in the cultivation of cereals.

It also considerably reduces the levels of heavy metals, pesticides and mycotoxin Don, which may have accumulated on the pericarp and which are harmful to health.

English

English Italiano

Italiano Français

Français Русский

Русский Español

Español